Features and Benefits

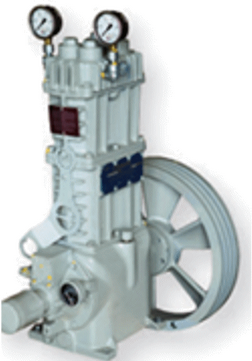

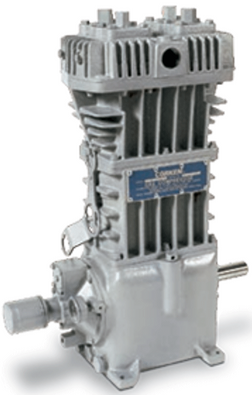

Reciprocating CORKEN Gas Compressors

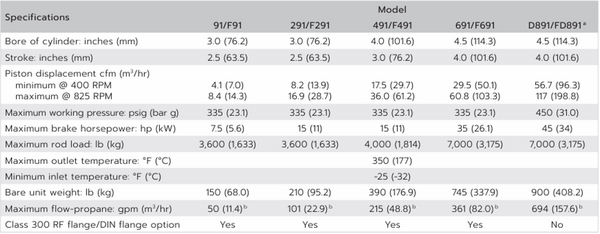

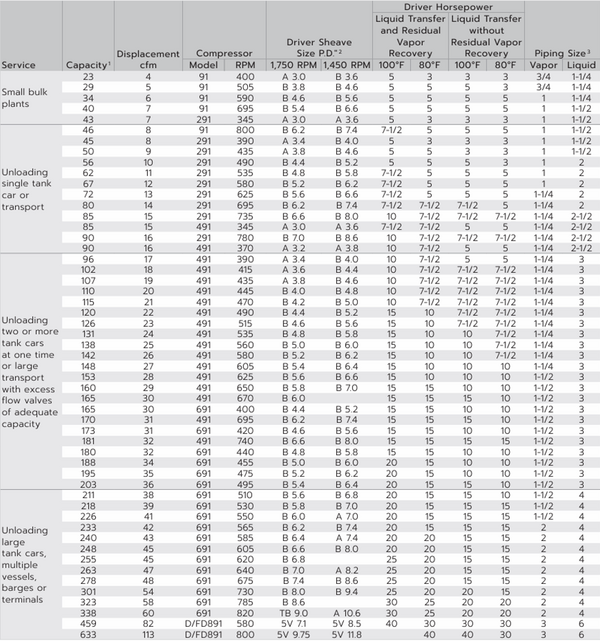

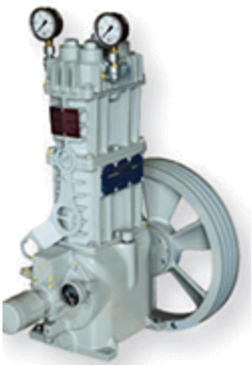

Corken offers five sizes of vertical, single-stage compressors (Models CORKEN 91, CORKEN 291, CORKEN 491, CORKEN 691, and CORKEN 891) for LPG/NH3 applications. The CORKEN compressors are available with threaded NPT or Class 300 RF flanged connections and cover a full range of capacities ranging from 7.0 to 198.8 m3/hr of liquid transfer. The Class 300 RF flange dramatically improves leakage containment and structural integrity.

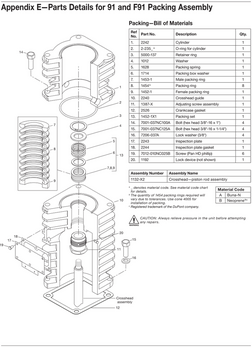

Piston rod packing design…

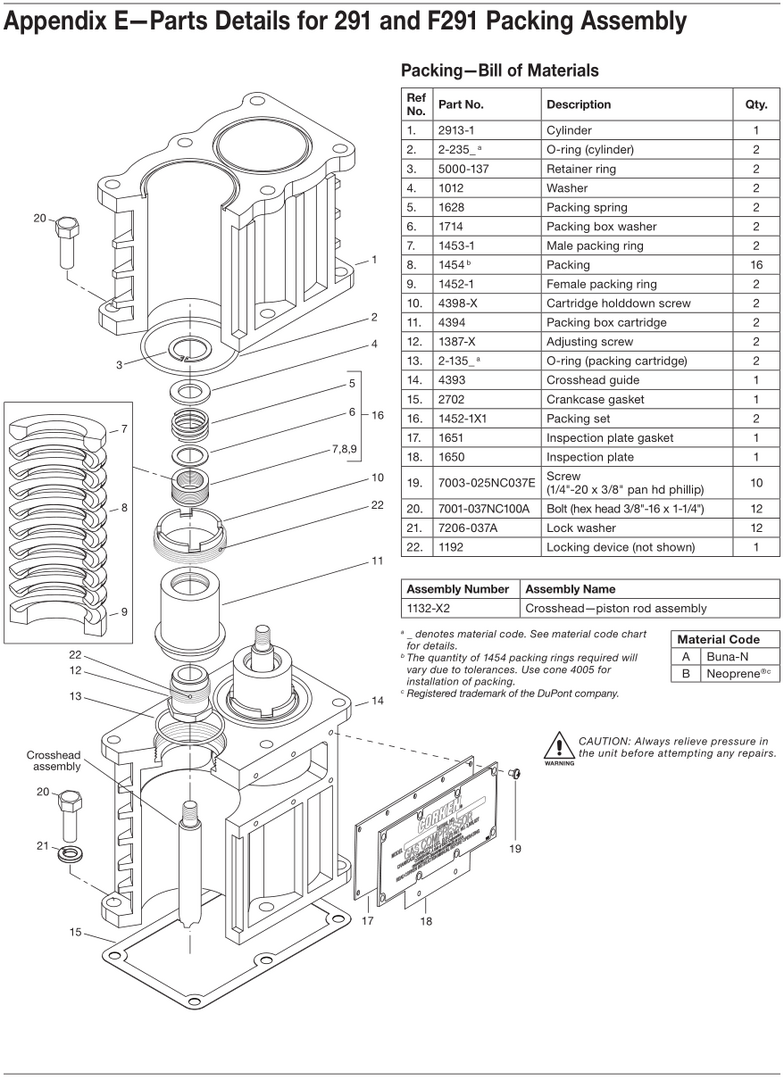

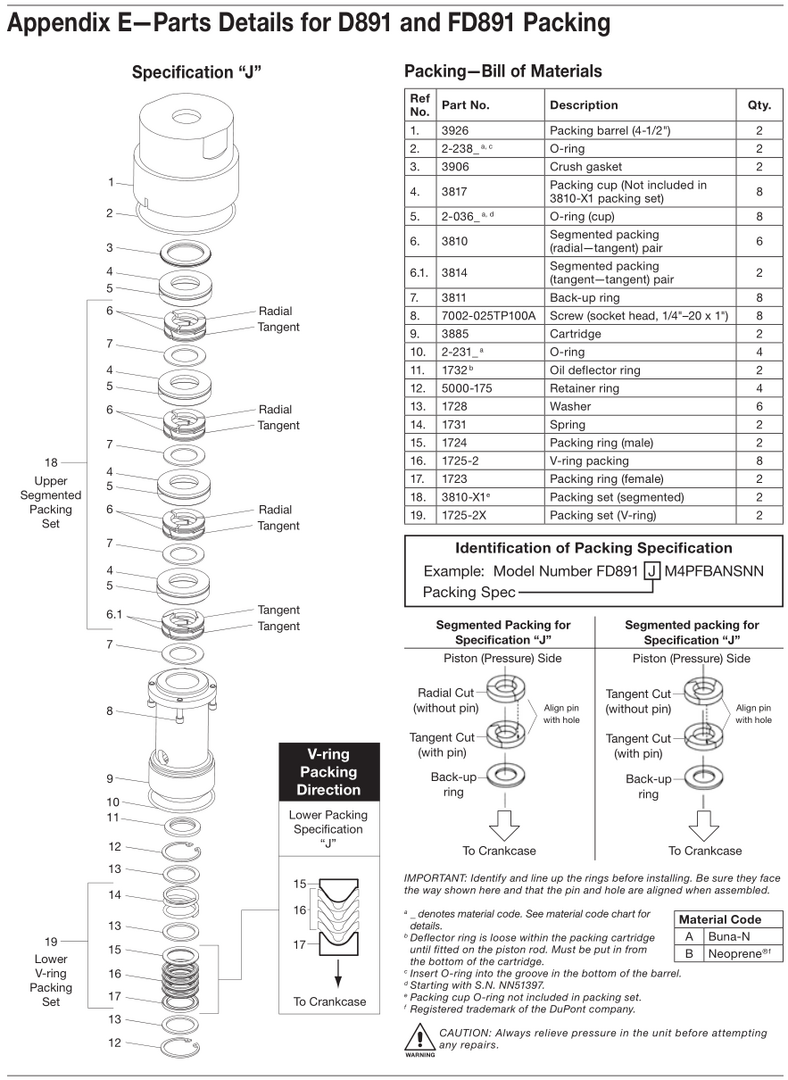

Corken’s standard LPG vertical compressors are a plain style design using one set of V-ring packing. Most of Corken’s LPG vertical compressors use a single set of V-ring packing (plain-style). The only exception is the model CORKEN 891 which uses a combination of V-ring packing and segmented packing. Even though the model CORKEN 891 is a D-style compressor, it is the only D-style compressor that is not oil free. All other D-style compressors are oil free. V-ring packing consists of several V-rings, male and female packing rings, washers, and a spring while segmented packing consists of packing cups, spacers, O-rings, segmented packing, backup rings, and a spring. None of the plain style packing arrangements are oil-free designs. If oil-free gas compression is required, Corken’s D- or T-style compressors are recommended.

Single-stage design...

Corken’s single-stage compressors are typically used in applications where the gas compression ratio is less than 5:1. Generally, applications with relatively low differential pressures are well suited for a single-stage compressor. Transport, rail car, and marine unloading by vapor differential are examples of this type of application.

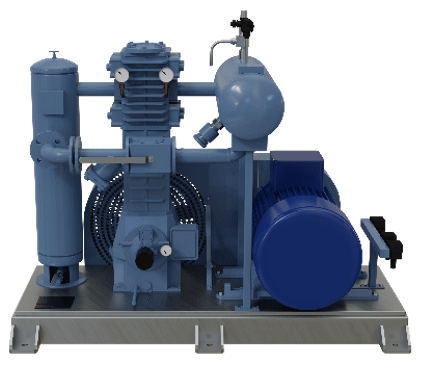

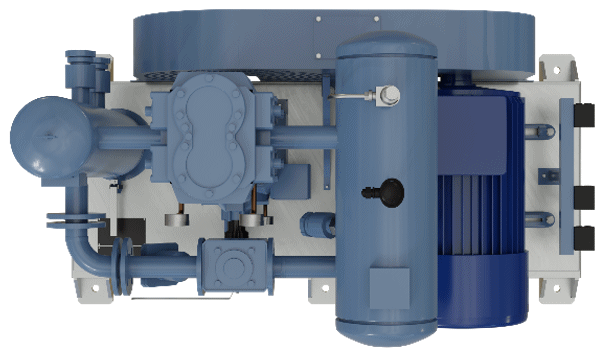

Custom engineered compressor packages available..

EDS offers standard mountings designed specifically for liquefied gas transfer, vapor recovery, and gas booster applications. If they do not meet the specifications of the application, EDS can supply a custom engineered package. Skid mounted units are supplied with control panels, safety controls, pulsation dampeners, receiver tanks, valves, and other special accessories as required. For more details, please contact EDS engineering team

Reciprocating CORKEN Gas Compressors Vertical

a Double-acting vertical compressor.

b Maximum flow is based on 825 RPM or maximum hp, 30 psid. Capacities shown are based on 100°F (37.8°C) and will vary depending upon piping, fittings, product being transferred, and temperature. The factory will supply a detailed compressor analysis if required.

Reciprocating CORKEN Gas Compressors Horizontal

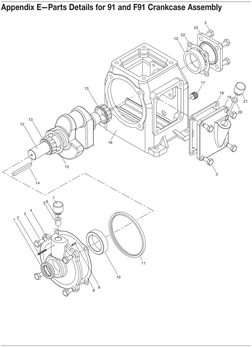

The CORKEN 91 dry-running piston compressor is the smallest compressor in the CORKEN LPG Compressor series.. Typical application is: transfer of LPG from road tankers, pressure increase in gas supply systems, etc

Operation CORKEN 291 compressor :

| Max piston replacement, m3/h | 13 |

| Min suction pressure, bar | 0,2 |

| Max suction pressure, bar | 23 |

| Weight bare compressor, kg | 68 |

| Recommended motor power, kw | 3,6 |

| Max Motor power, kw | 5 |

| Connections | 3/4” NPT |

Available as bare compressor or as EDS -Corken complete unit (skid)..

Available driver: Exe Motor, Exd Motor, Diesel engine

Customized design available.

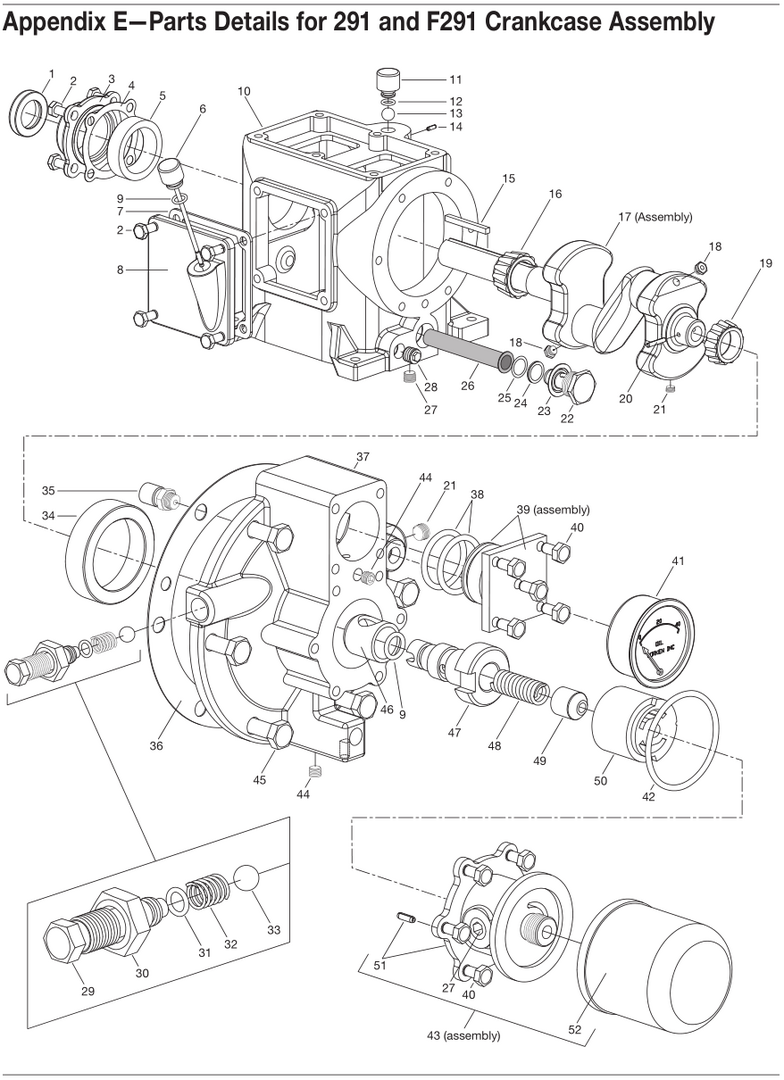

The CORKEN 291 dry-running piston compressor is the most popular CORKEN compressor for use in LPG road tankers..

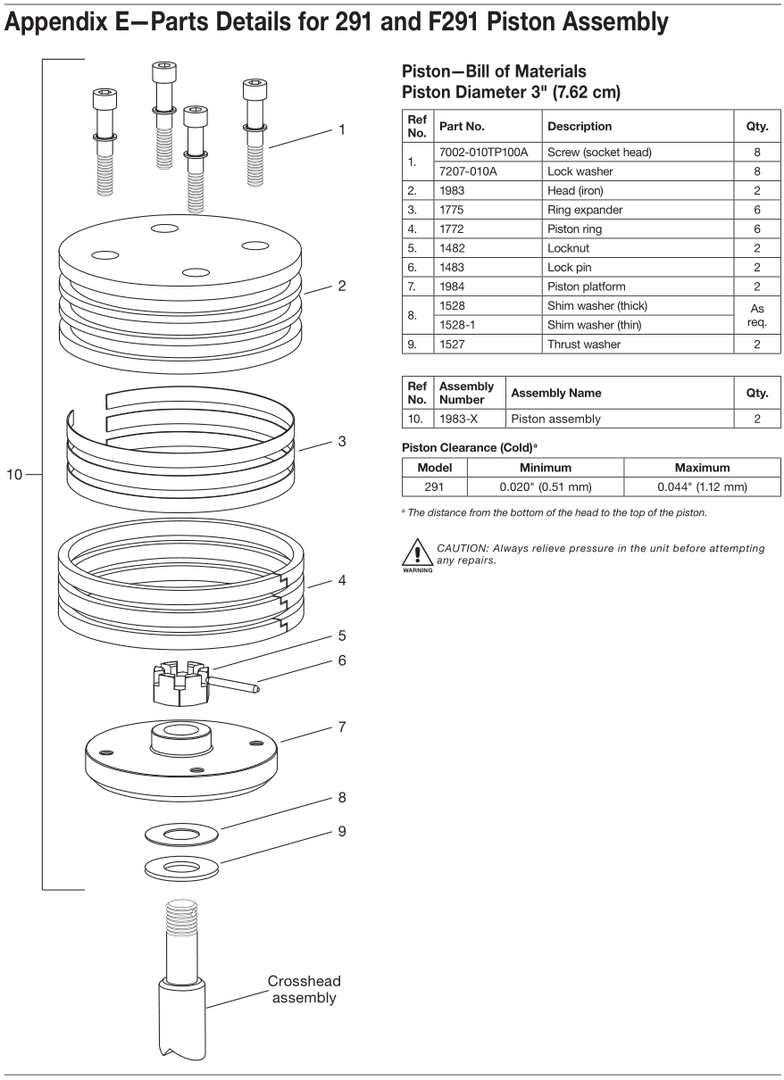

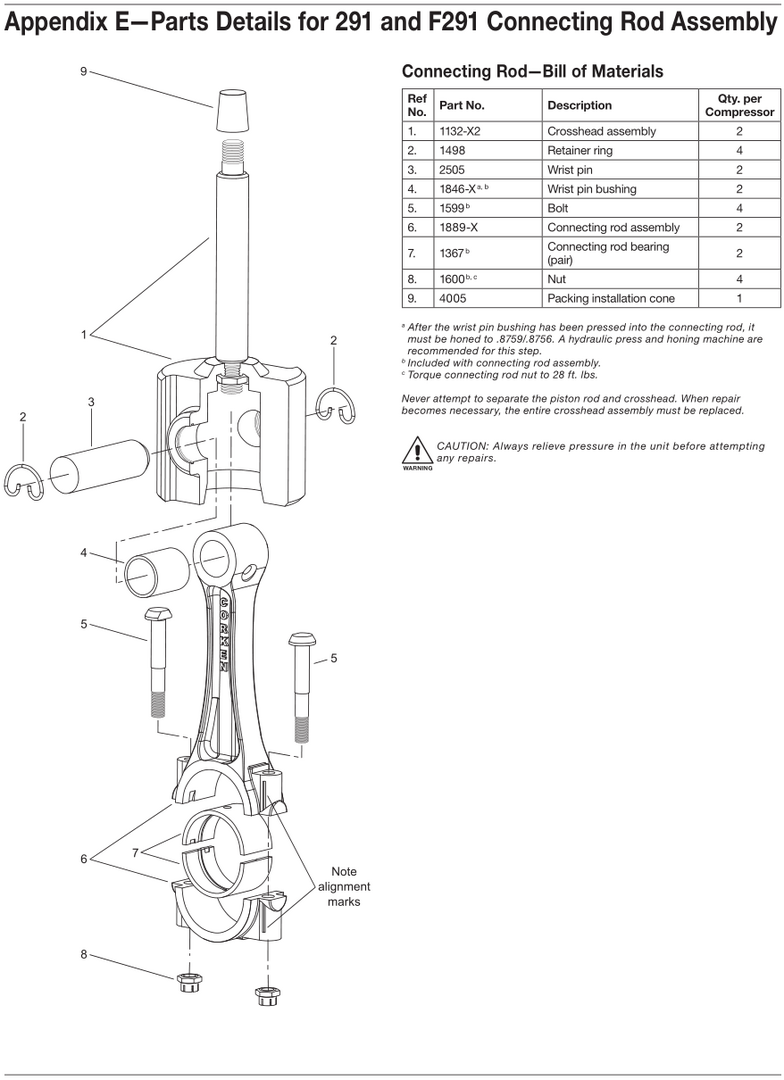

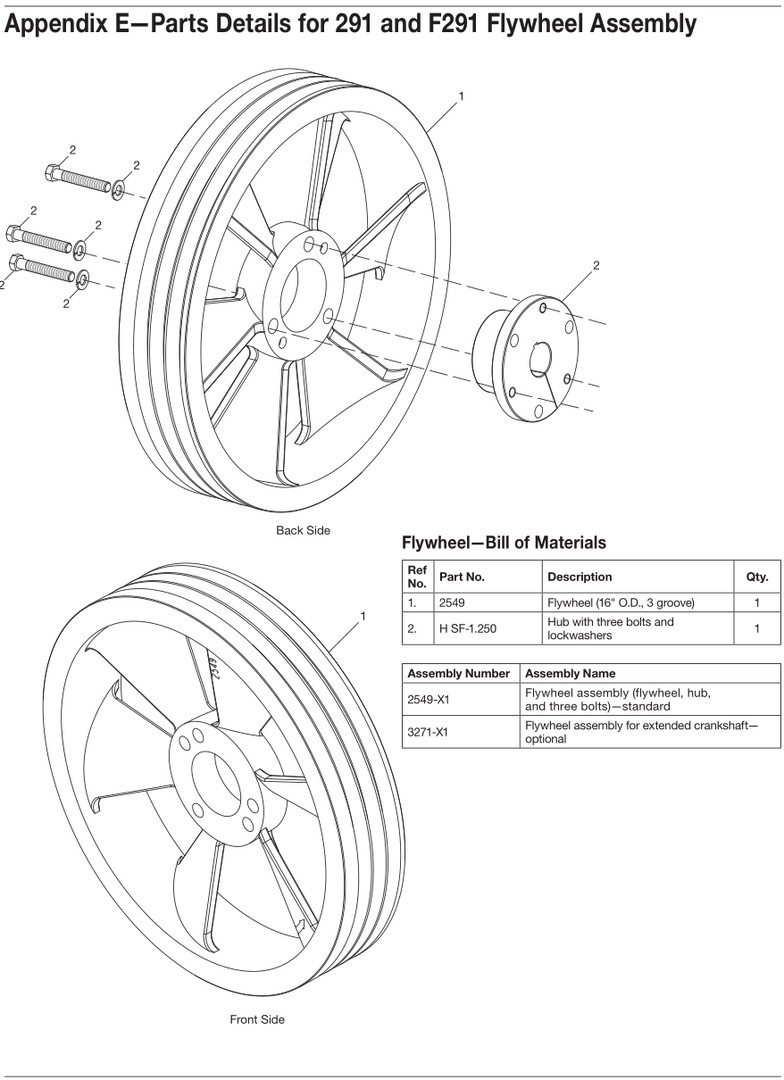

Operation Data Corken 291 Compressor:

| Max piston replacement, m3/h | 27 |

| Min suction pressure, bar | 0,2 |

| Max discharge pressure, bar | 23 |

| Weight bare compressor, kg | 96 |

| Recommended motor power, kw | 5 |

| Max Motor power, kw | 1 |

| Connections | 3/4” NPT |

Available as bare compressor or as EDS -Corken 291 complete unit (skid)..

Available driver: Exe Motor, Exd Motor, Diesel engine

Customized design available.

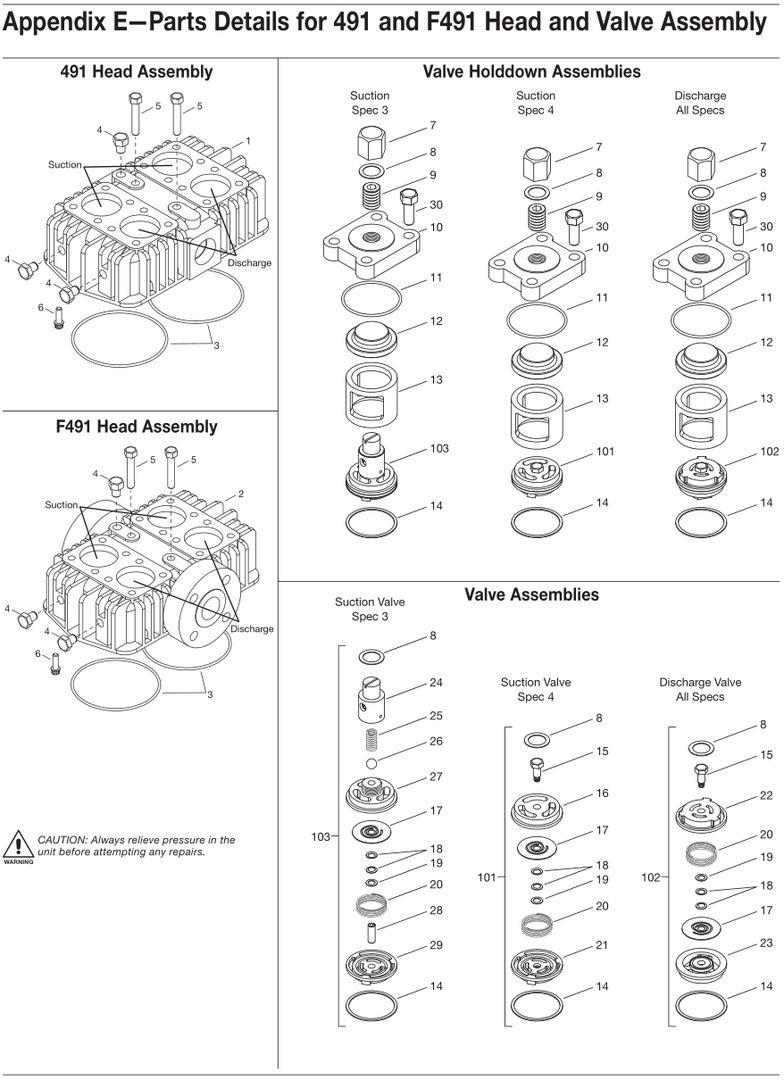

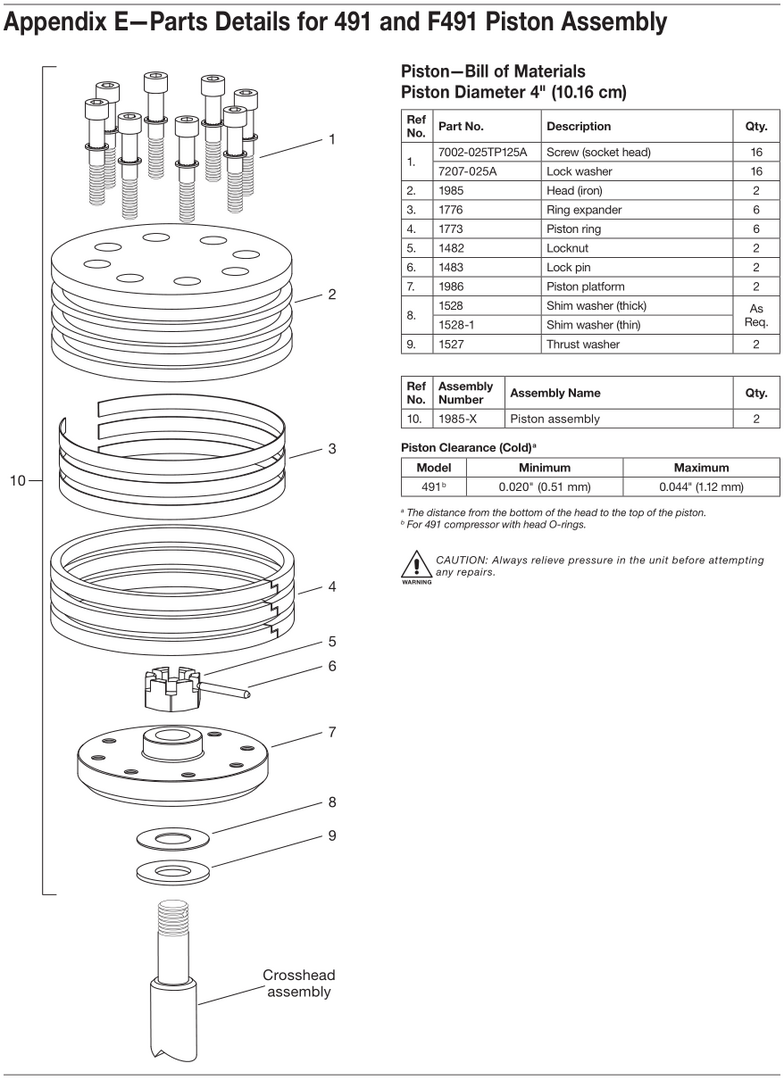

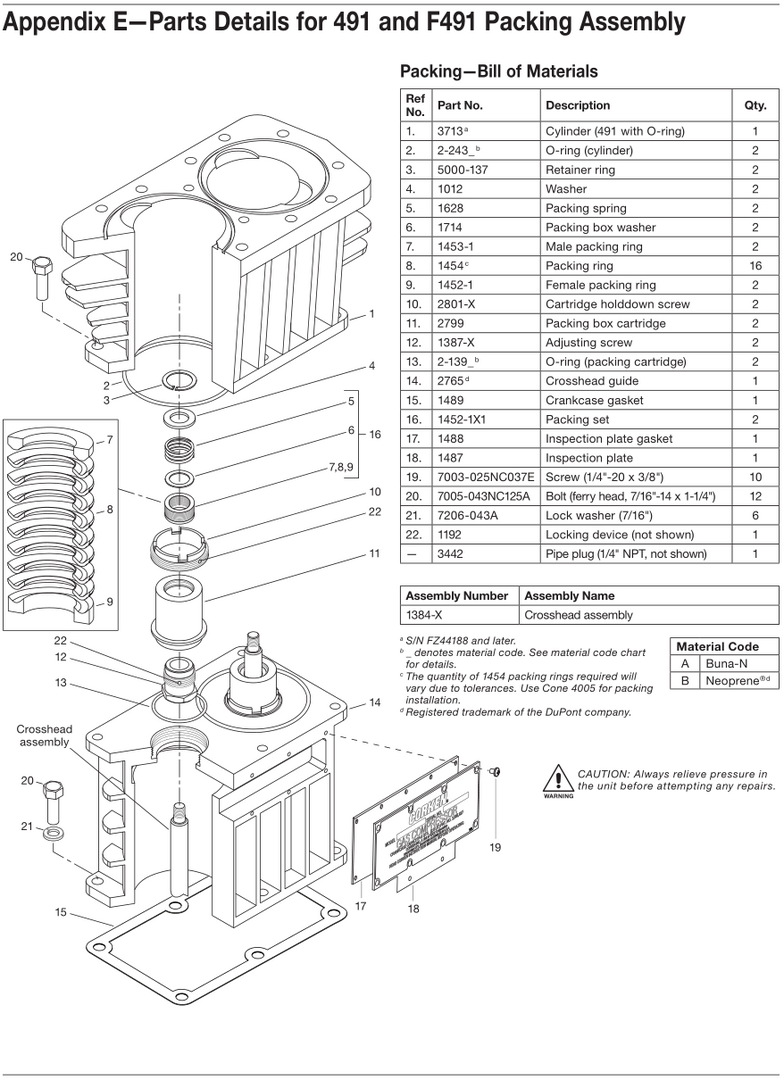

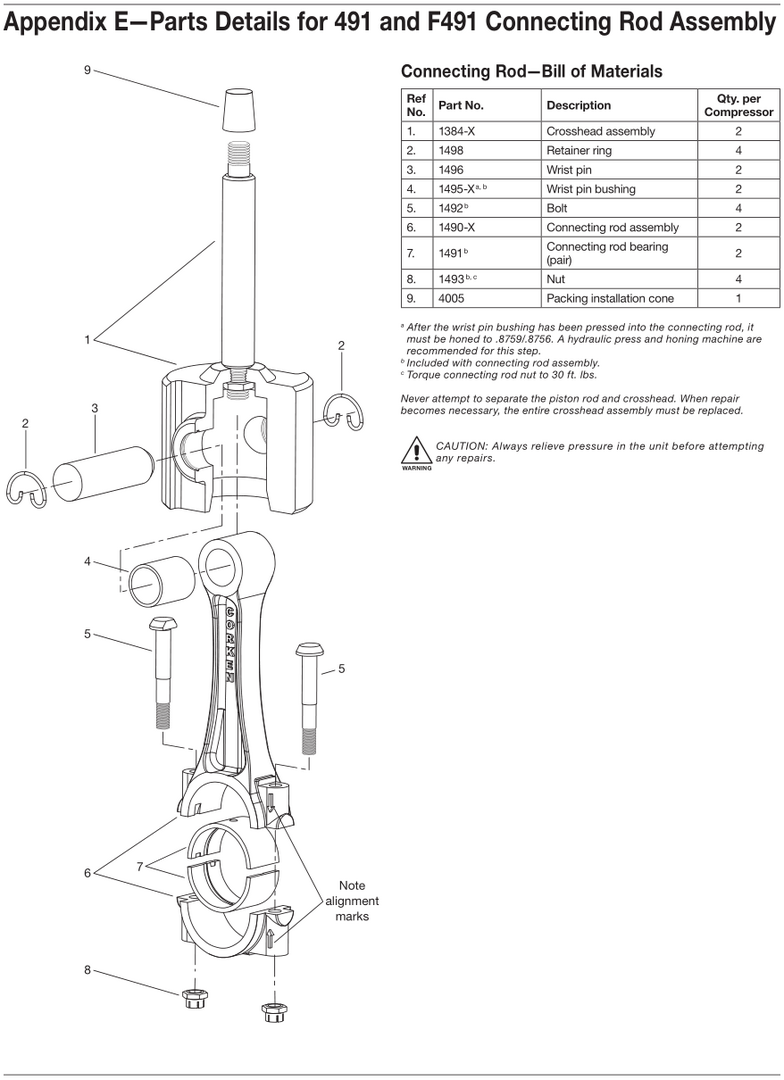

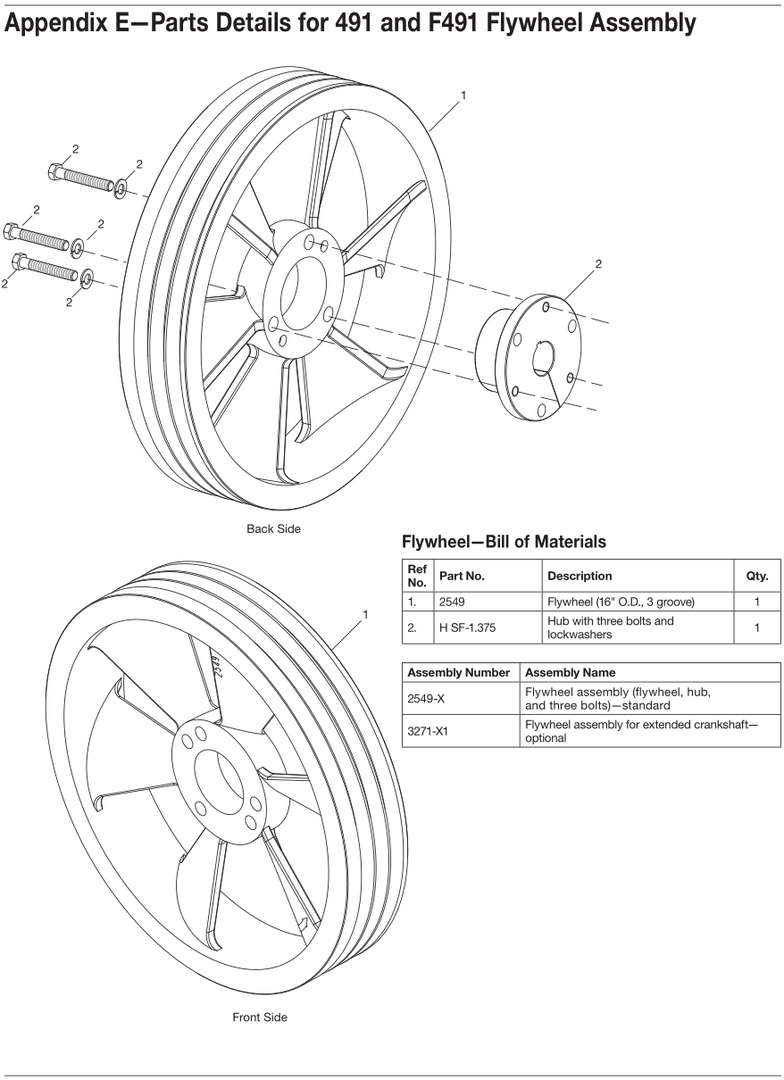

With a displacement of 60 m3/h, CORKEN 491 Compressor is very often used in smaller LPG terminals for fast LPG road tanker unloading …

Operation Data Corken 491 Compressor:

| Max piston replacement, m3/h | 58 |

| Min suction pressure, bar | 0,2 |

| Max discharge pressure, bar | 23 |

| Weight bare compressor, kg | 177 |

| Recommended motor power, kw | 10 |

| Max Motor power, kw | 15 |

| Connections | 1-1/4” NPT |

Available as bare compressor or as EDS -Corken 491 complete unit (skid)..

Available driver: Exe Motor, Exd Motor, Diesel engine

Customized design available.

Operators of medium-sized LPG terminals - with the simultaneous unloading of 1-3 rail cars often use CORKEN 691 LPG compressors… CORKEN 691 Compressors can be installed in the row for parallel operation

Operation Data Corken 691 Compressor:

| Max piston replacement, m3/h | 108 |

| Min suction pressure, bar | 0,2 |

| Max discharge pressure, bar | 23 |

| Weight bare compressor, kg | 338 |

| Recommended motor power, kw | 17 |

| Max Motor power, kw | 26 |

| Connections | 1-1/2” NPT |

Available as bare compressor or as EDS -Corken 691 complete unit (skid)..

Available driver: Exe Motor, Exd Motor, Diesel engine

Customized design available.

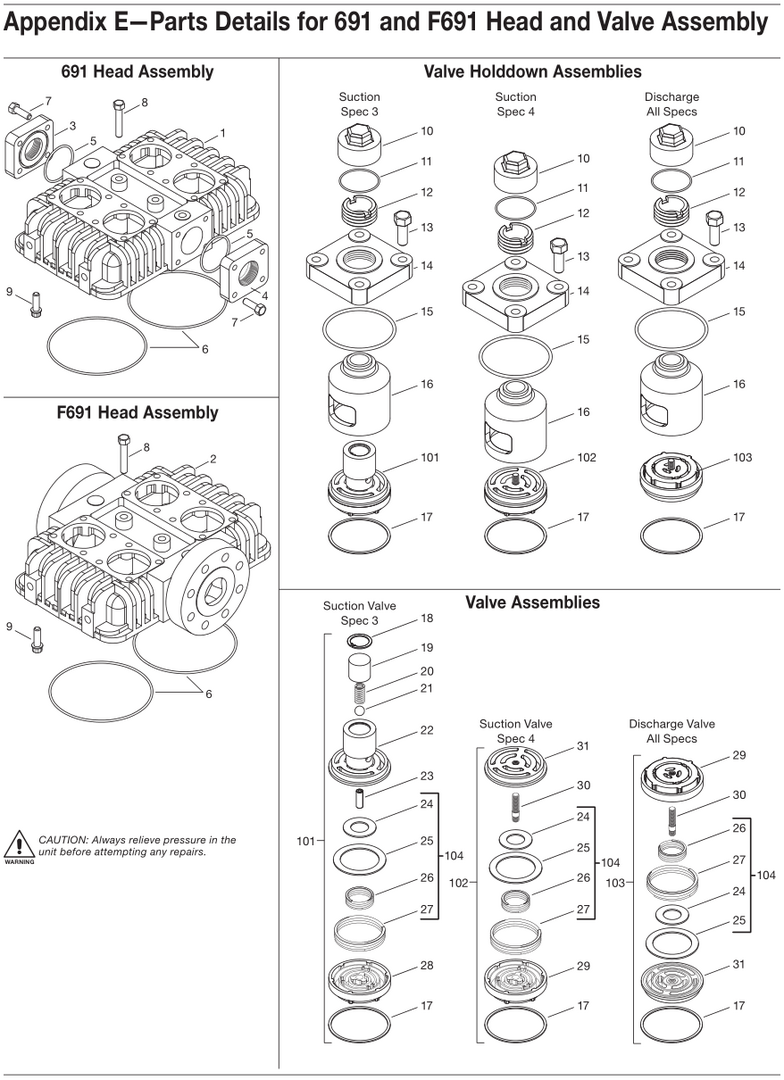

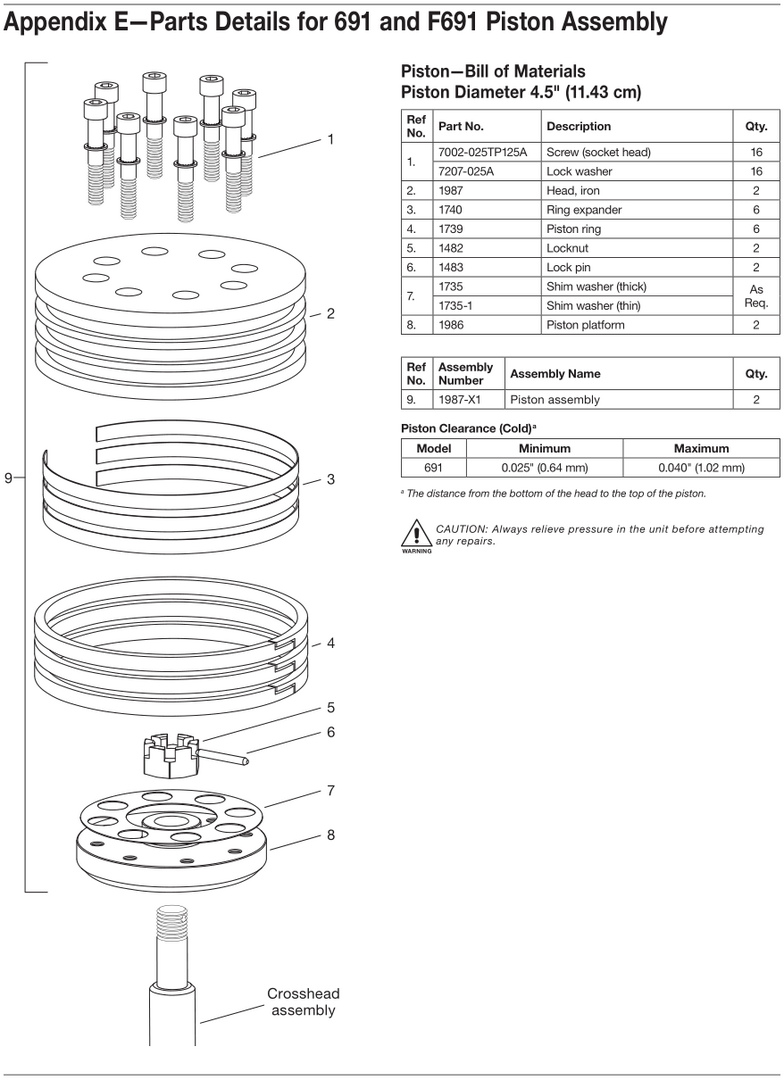

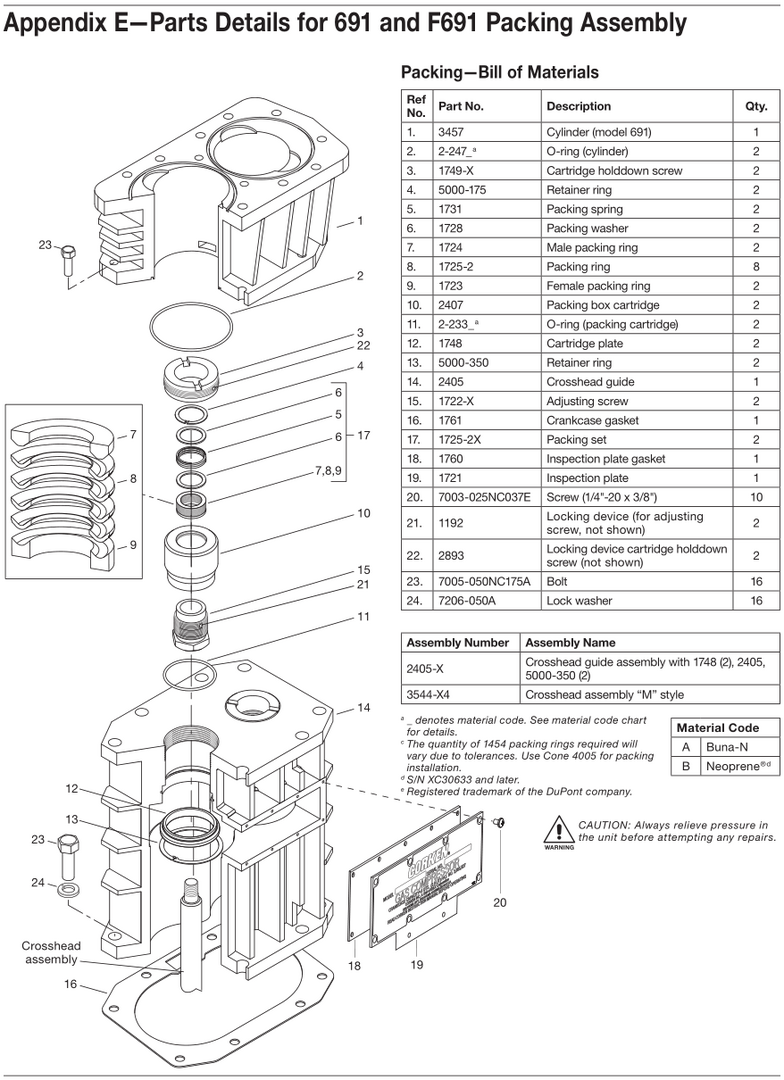

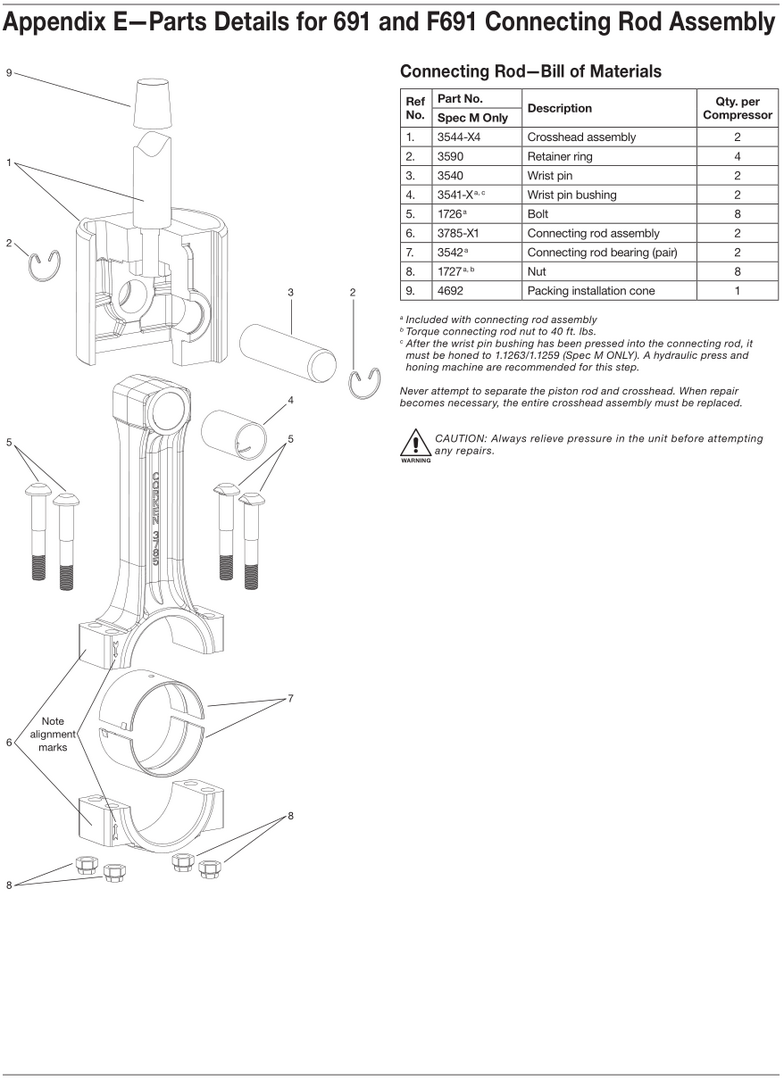

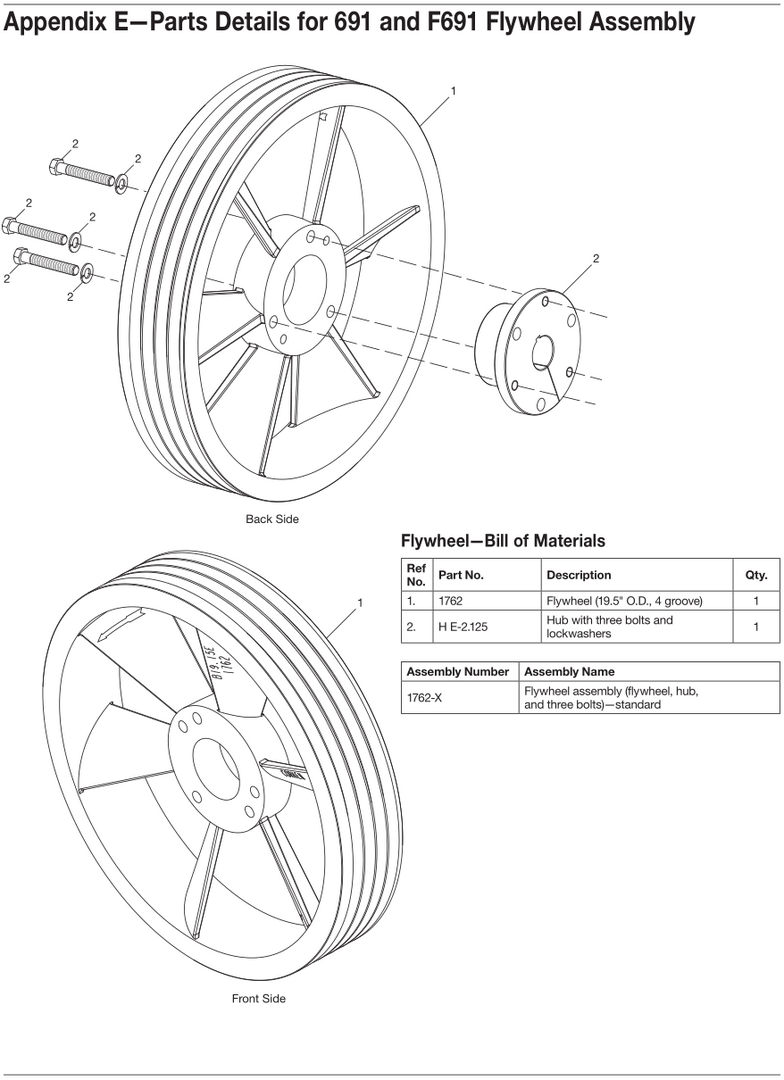

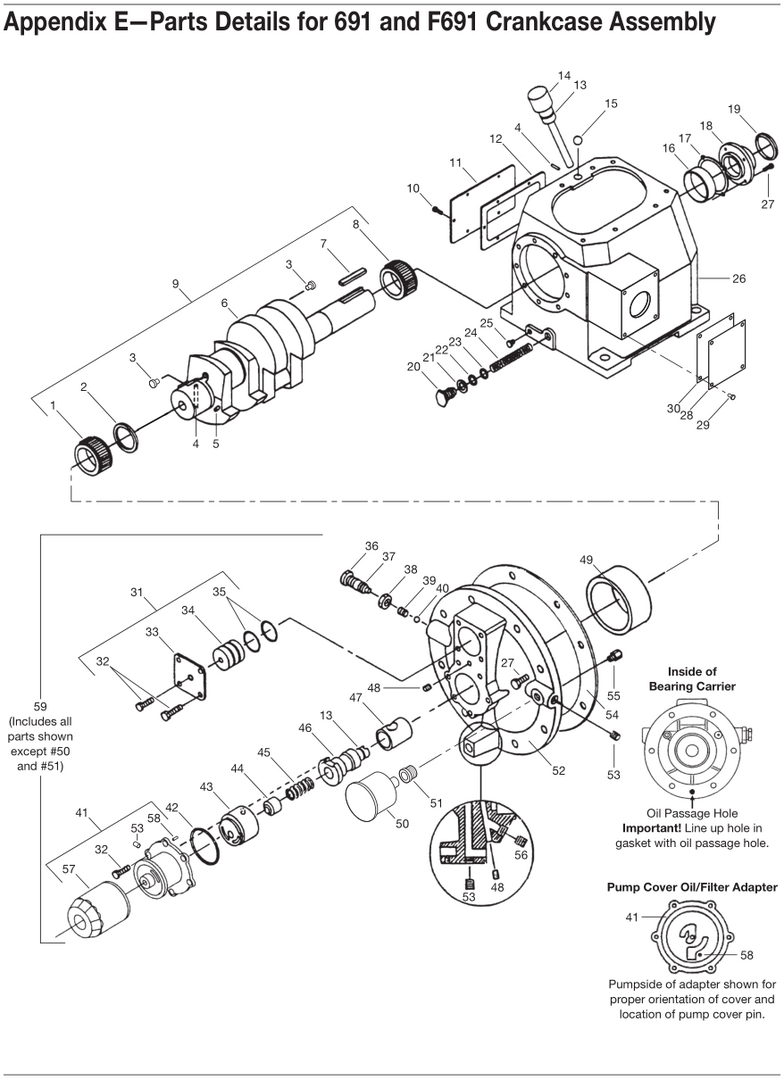

Spare parts for Corken 691 LPG Compressor

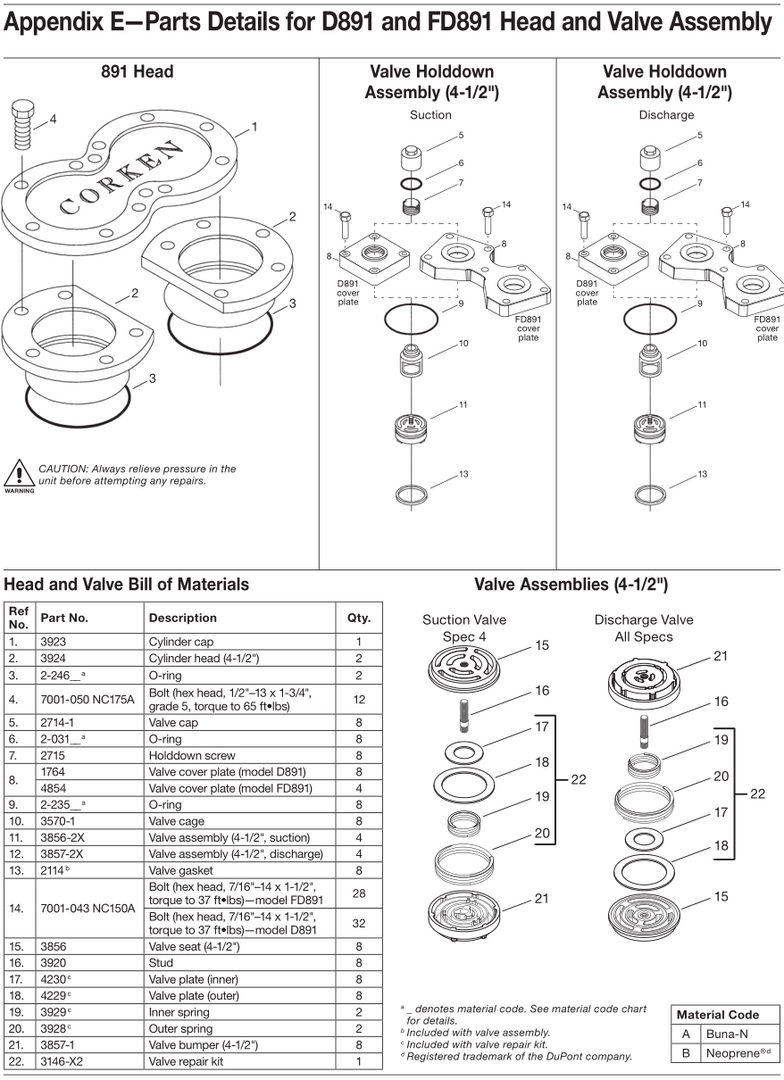

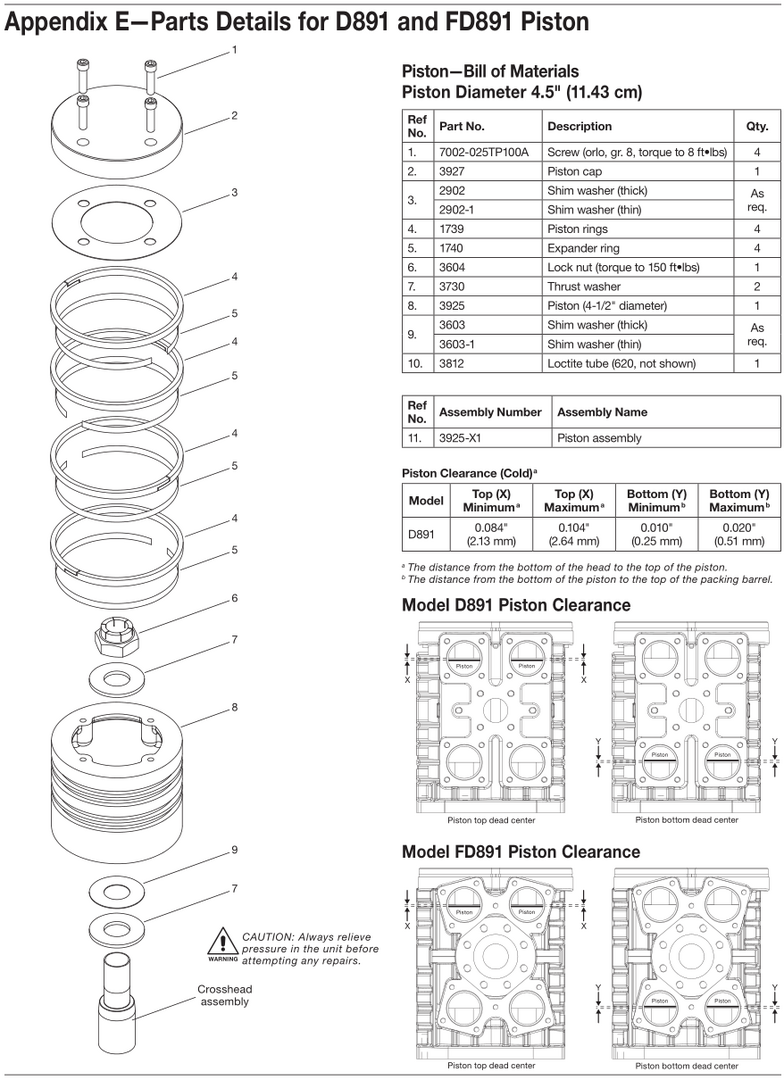

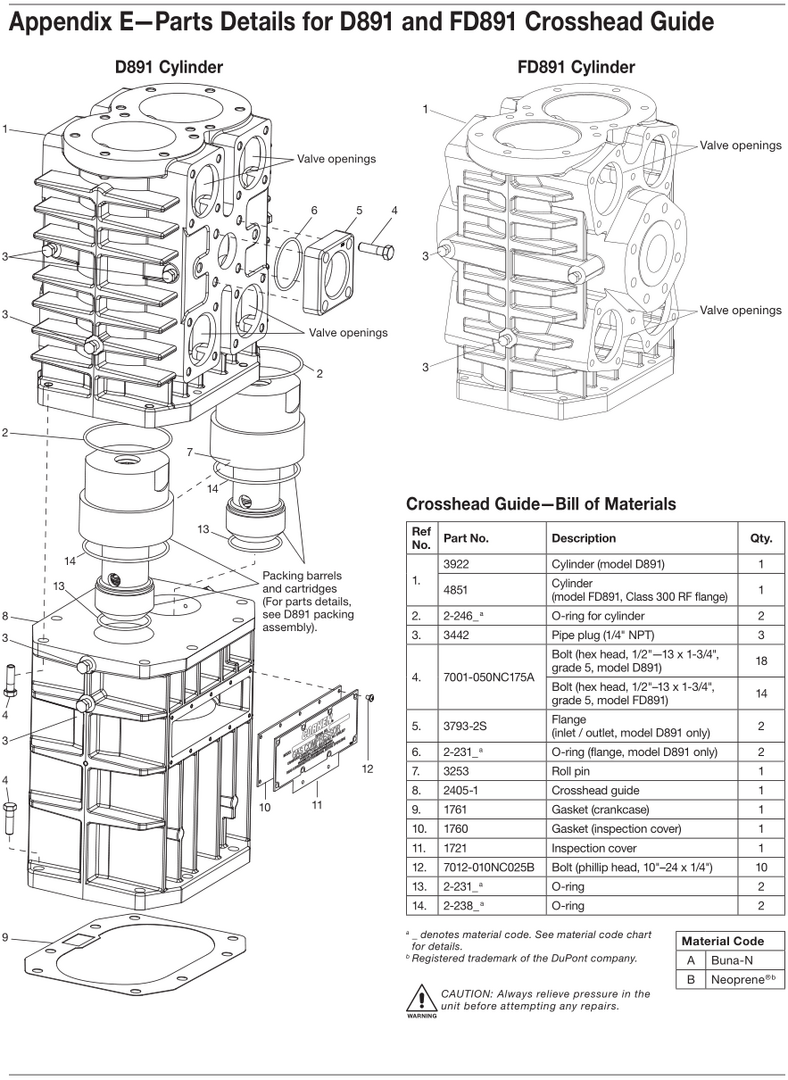

CORKEN FD 891 is the largest vertical LPG compressor in the Corken LPG family. Typical application is - the large LPG terminals, in which up to 20 tank cars can be unloaded at the same time

Operation Data Corken FD 891 Compressor:

| Max piston replacement, m3/h | 200 |

| Min suction pressure, bar | 0,2 |

| Max discharge pressure, bar | 31 |

| Weight bare compressor, kg | 930 |

| Recommended motor power, kw | 30 |

| Max Motor power, kw | 34 |

| Connections | 2” ANSI |

Available as bare compressor or as EDS -Corken FD 891 complete unit (skid)..

Available driver: Exe Motor, Exd Motor, Diesel engine

Customized design available.